Food Mixing/Blending Models

High Shear Mixers

|

|

| Inline SLIM systems are ideal for the continuous addition of solids such as Carbopol and Xanthum gums to assist in the stabilization of food products. |

The MegaShear is the ultimate in High Shear designs. This unit produces sub-micron food emulsions, at faster throughput rates, and at less cost. Units are supplied with sanitary connections, and on carts for portability. |

|

|

| The patented rotor/stator design of the Ross SLIM food technology creates an intense vacuum, thereby inducting hard to wet solids and liquids into the rotor/stator interface. |

This custom vacuum/pressure food reactor was designed and built to meet the special needs of a client. All polished stainless steel construction and a lifting cover provide complete access for cleaning between batches. |

|

|

| This Inline system was built for use in either continuous or semi-continuous service. It offers the capability of recirculation within the process vessel, or diverting direct to an ongoing process. |

This Inline SLIM food system is mounted on a portable cart with controls. This design allows use of the SLIM system with multiple vessels in different areas of a manufacturing plant. |

|

|

| Ross High Speed Food Dispersers are perfect for straight forward dispersion requirements of medium viscosity products. The Disperser is supplied with a hydraulic lift so that it can be used with multiple vessels. |

Vertical systems are set up to incorporate hard to wet food powders. The recirculation piping and tangential inlets allow for precise control of the liquid flow, and the vortex to assist in solids additions. |

|

|

| The Model 100LSK Lab rotor/stator mixer is powered by a 1 HP variable speed (up to 10,0000 rpm) motor. Included are digital readouts. A push button lift system is included. This model is perfect for food development applications. | 400DL Bench-top mixers are perfect for the development of new products, in small quantities. The ½ hp drive and optional 2-gallon recirculation vessel allow the use of small quantities of materials in the development process. |

Control Systems

|

|

| We offer a selection of PLC and PLC based controls with many options for integration into your existing equipment, or or entirely new installations. |

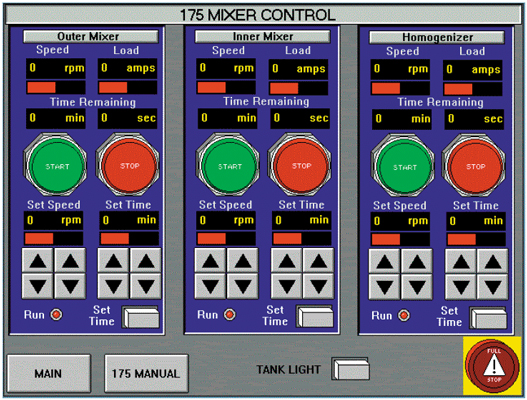

Numerous control screens are available including the screen shown above. This provides for automated multi-shaft mixer control of speed and time. |

|

|

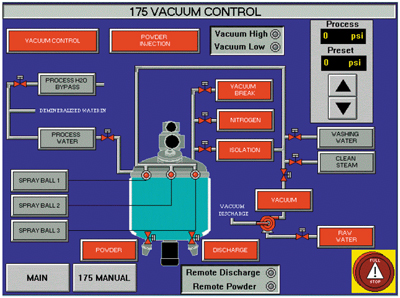

| The screen shown above controls vacuum and powder induction levels. |

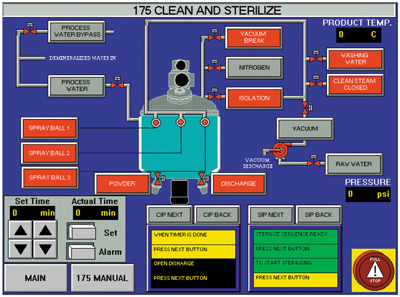

Cleaning and Sterilizing is critical between batches. This operation is controlled from this screen. |

|

|

| Panels of different sizes and shapes are available for stand alone floor installation. We have the experience needed to build fully automated systems. |

Purged panels are built for hazardous areas. We offer a working knowledge of cGMP, OQ, IQ, and system vaildation. |

|

|

| Touchscreen panels are convenient to use on the shop floor. Many include PLC based recipe control software. |

Small stainless steel panels are built in a variety of configurations. |

Multi Shaft Food Mixers

|

|

| This Turboemulsifier includes counter-rotating sweep blades and a homogenizer mounted in the bottom center of the vessel. Unit is designed for vacuum/pressure operation. |

Our Versamix is normally supplied with three seperate agitators including an anchor, high speed disperser and a rotor-stator homogenizer. The unit shown is supplied with a special helical anchor design and is ideal for higher viscosity food mixng needs |

|

|

| The 10 gallon VersaMix is ideal for pilot plant operation in a food manufacturing plant. The 10 gallon model VMC VersaMix is shown with all stainless steel construction, and a complete seperate control system. The mixer is raised to permit direct discharge into containers. |

Model VMC 100 is provided with a standard three wing anchor, high speed disperser and a rotor-stator homogenizer. A special SLIM (solid, liquid introduction manifold) is also provided. Stainless components are polished to a 320 grit finish. |

|

|

| This 15 gallon VersaMix was supplied with a special conical bottom to insure that all mixed materials will drain after the mix cycle is completed. Scrapers are provided on the anchor to maximize heat transfer from the jacketed vessel walls. |

A 40 gallon model VMC, triple shaft mixer with the vessel elevated and mounted on non-sparking caster wheels, to allow easy movement of the vessel within the process plant. Unit is designed for full vacuum operation. |

Ribbon & Vertical Blenders

|

|

| Ribbon Blenders are available from 1 through 515 cu.ft. capacity. Our food blenders are constructed in stainless steel and are polished to ensure easy cleaning. Flexible cover configurations and discharge valve options are supplied.

|

This 120 cu. ft. model includes our standard enclosed drive design and hinged cover sections. The interior and exterior stainless surfaces are polished to a 150 grit finish. |

|

|

| Our standard non-sanitary model is normally acceptable for use in most food applications. These units have a standard 80 grit finish on the stainless steel components and are supplied with covers as needed. |

Ribbon Blenders are often used for vacuum or pressure service. This 100 cu.ft. unit also includes a jacket for temperature control, and a hydraulically operated cover lift. |

|

|

|

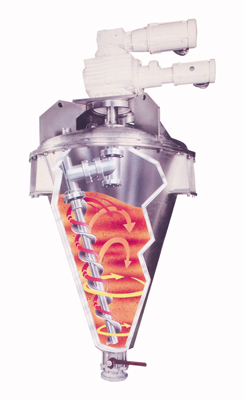

Vertical Blenders are perfect for products that demand gentle blending. They consume a small footprint and use low horsepower to blend even high density products. Vertical Blenders are known for complete discharge, easy cleaning, and short blend cycles.

|

This Vertical Blender is constructed in stainless steel and polished for sanitary applications. It includes a jacket for heating or cooling and is designed for full vacuum operation. Models are available from 1 to 500 cu. ft. capacity. |

Food Mixing & Storage Vessels

|

|

|

Portable 50 Gallon Storage Vessel on wheels with a removable cover and jacket for heating and cooling. Unit has a 150 grit sanitary finish on all stainless parts.

|

Vertical Storage Vessels are available in many sizes, standard or special. They are built to include dimpled jackets, agitators, special cover and bottom openings, and finishes as required. |

|

|

| The 500 gallon vacuum storage vessels shown, are all polished to a 150 grit finish. Each includes a dished bottom, and a variety of nozzles in the cover. |

Vessels designed for vacuum/pressure service often include propeller agitators. The vessels shown include a 320 grit finish and are mounted on legs with load cells to monitor batch sizes. |

|

|

|

A 500 gallon capacity vacuum and jacketed mix vessel includes a slow speed propeller agitator. This agitator is used to keep all product in motion and to minimize settling before packaging.

|

50 gallon vacuum/pressure vessel designed for operation to 50 psi. Includes a 100 psi code stamped jacket and a double mechanical seal on the propeller agitator. |

|

|

|

250 gallon mix tank with controls is built on a portable cart to enable use in different areas of the manufacturing plant. The tank is designed for vacuum service and includes an agitator.

|

A 500 gallon transfer vessel is designed for vacuum/pressure service to 100 psi. Included are many special openings in the cover for charging of minor ingredients. |

Tumble Blenders

|

|

| Double Cone Blenders are most often used for the intimate dry blending of free flowing solids. The solids being blended in these units can vary in bulk density and in percentage of the total mixture. Materials being blended are constantly being intermixed as the Double Cone rotates. Normal cycle times are typically in the range of 10 minutes, however they can be less depending on the difficulty of blending. Ross Double Cone Blenders are in stock in 5, 10 and 15 cu.ft. capacity. A full range of sizes from 1/2 to 80 cu. ft working capacity is available. Each is constructed of type 316-stainless steel and is internally polished to a 240 grit sanitary finish. The exterior is polished to an easily cleaned 150-grit finish.

|

V-Blender designs are most often used for the intimate dry blending of free flowing solids. The solids being blended in these units can vary in bulk density and in percentage of the total mixture. Materials being blended are constantly being split and intermixed as the shell rotates. Normal cycle times are typically in the range of 15 minutes, however can be less depending on the difficulty of blending. V-Blenders are stocked in 5, 10, and 15 cu.ft. capacity. Each is constructed of type 316-stainless steel and is internally polished to a 240 grit sanitary finish. The exterior is polished to an easily cleaned 150-grit finish

|

Copyright 2014 Charles Ross & Son Company. All rights reserved.

Copyright 2014 Charles Ross & Son Company. All rights reserved.